Speak to our experts today

X

If you would prefer, you can contact us on 0151 480 1212.

X

If you would prefer, you can contact us on 0151 480 1212.

As the UK’s leading supplier for industrial bulk bags, we can help you with everything from bespoke options (customised bulk bags) to bulk bags per your specific use case. Have a look at our info here, then get in touch with us to tell us more about what you need.

Bulk bags can be manufactured to endless designs and specifications, depending on how you need your products to be filled, stored, transported and discharged. So it’s well worth thinking about:

The name ‘bulk bag’ covers any kind of FIBC or flexible intermediate bulk container. They’re an ideal way for you to transport and store dry, free flowing materials safely, securely and cost effectively.

Bulk bags can be certified to carry contents weighing anything from 50kg up to 2000kg. The heavier your product is, the heavier the grade of fabric needed to manufacture the bag so it conforms to the safe working load. A bulk bag can carry up to 1000 times its own weight.

Bulk bags are predominantly made from polypropylene (PP), a high-strength thermoplastic that’s very strong yet flexible.

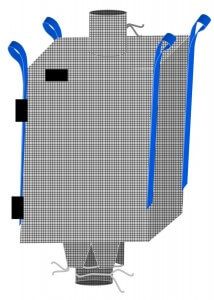

The polypropylene is extruded in tubular form and then sliced into threads and woven together (warp and weft) to form a very strong, durable fabric.

Food-grade bulk bags are made from this bag fabrics as they are produced in different thicknesses depending on the weight your bag needs to safely carry.

So a fabric that needs to carry a weight of 2000kg will be heavier and stronger than a fabric that only needs to carry 500kg.

d.a.pak specialises in failsafe food-grade BRC-compliant FIBC bulk bags that are expertly designed to meet the strict requirements of the food industry.

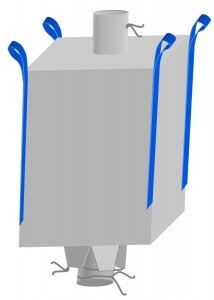

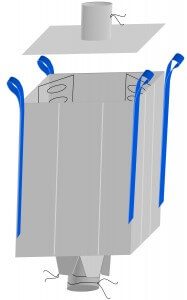

With a continuous “U” shaped panel that connects two side walls, these bags give you a really high safe working loading weight – reducing your packing and transport costs.

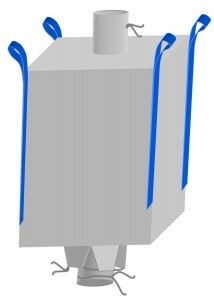

Made from 100% virgin woven polypropylene, with four separate pieces of fabric stitched together, these bags keep their shape better than some others – making them perfect for stacking.

Really easy to use with forklifts and cranes, these are a great time and effort saver, and a cost-effective choice, too. Made from a single piece of material (making them cheaper to produce) and without any side seams, they give you the added bonus of allowing high vertical pressure.

Bulk bags can be made for either single trip or multi-trip use, and you can find out which yours is from the safety label that’s attached to it.

A safety factor of 5:1 tells you that your bulk bag is for single trip use only – so you can only fill it once, but it can be lifted several times on its journey.

A safety factor of 6:1 tells you that your bulk bag is for multi-trip use and can be emptied and refilled several times – so this is your more economical and environmentally-friendly option.

The safety label will also tell you the ‘safe working load’ your bag can carry – for example, 1000kg. And it will tell you the test house, certificate number and certificate date, together with your bag’s manufacture date and batch number. All of this info is given to show that your bag’s been tested to perform to a safe standard, and so you can trace every step of its production.

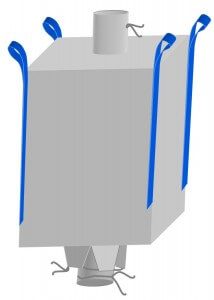

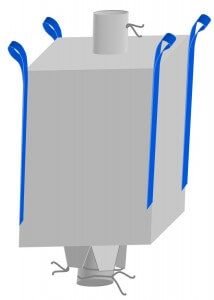

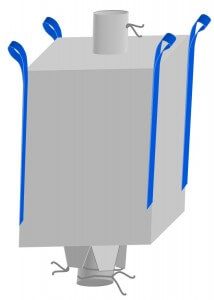

Bulk bags can have a filling spout which can be attached and tied to a machine or hopper feeder pipe, this allows the product to be filled directly into the bag and tied off once complete.

Skirt or duffle tops are an ideal way to fill bulk bags from a free flowing conveyor feed. The bag is effectively fully open on the top allowing maximum opportunity for materials to free fall and fill the bag.

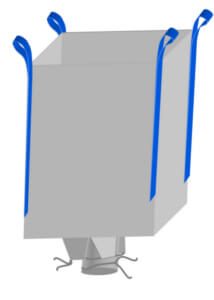

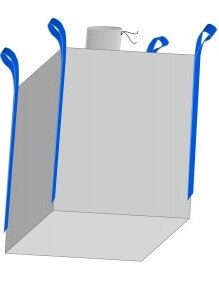

Plain base with no method for discharge.

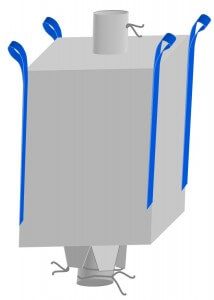

The most common way to empty a bulk bag is through a discharge spout. These spouts are folded (swan necked) and tied so they effectively form a flat base when not in use however when emptying the contents of the bag the spout can be untied and extended to allow the product to flow safely out of the bag. By adjusting the tie on the spout you can determine the radius of the discharge spout which will allow you to effectively control the flow rate of product being discharged.

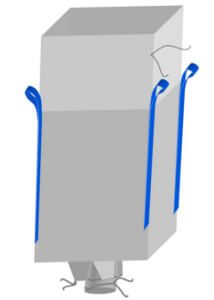

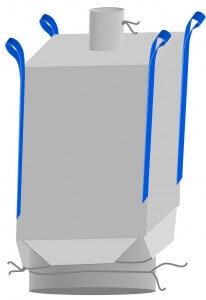

Bulk bags can be designed with a full base discharge with four panels of material sewn into each side of the bag that cross over to form a flat base within the bag. The bag will also have an outer flap that can be securely tied. When untying the base outer flap, the four inner overlapped panels release to form a full base discharge.