Speak to our experts today

X

If you would prefer, you can contact us on 0151 480 1212.

X

If you would prefer, you can contact us on 0151 480 1212.

d.a.pak specialises in failsafe food-grade BRC-compliant FIBC bulk bags that are expertly designed to meet the strict requirements of the food industry. With our full range of options and sizes, you’ll find the perfect bag for your food products, ensuring compliance with food safety standards and regulations.

During production of your bags, it’s obviously vital that no alien particles or threads come into contact with or contaminate the food product you’re packaging. So to make absolutely sure this never happens, our trusted global suppliers carry out a stringent number of safety processes and checks for us, in a sterile environment.

These include:

For extra protection, we can also supply your bags with food grade low-density polyethylene/linear low-density polyethylene or foil liners that you can insert and shape to fit perfectly inside.

Customise your food-grade FIBC bulk bags to align with your business requirements and branding. From size and design to printing and labelling, d.a.pak offers tailored solutions to enhance your brand presence and meet your specific packaging needs.

Bulk bags can be certified to carry contents weighing anything from 50kg up to 2000kg. The heavier your product is, the heavier the grade of fabric needed to manufacture the bag so it conforms to the safe working load. A bulk bag can carry up to 1000 times its own weight.

Bulk bags are predominantly made from polypropylene (PP), a high-strength thermoplastic that’s very strong yet flexible.

The polypropylene is extruded in tubular form and then sliced into threads and woven together (warp and weft) to form a very strong, durable fabric.

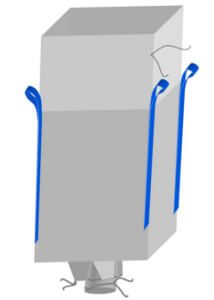

The most basic form for filling a bulk bag is using a fully open top which is ideal for products like sand and aggregate, where the product can flow easily into the bag and it does not need to be protected from the elements.

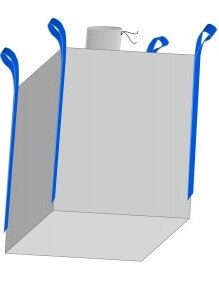

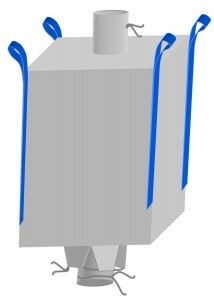

Bulk bags can have a filling spout which can be attached and tied to a machine or hopper feeder pipe, this allows the product to be filled directly into the bag and tied off once complete.

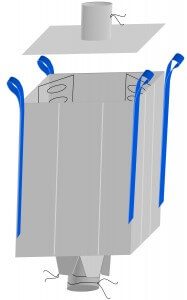

Skirt or duffle tops are an ideal way to fill bulk bags from a free flowing conveyor feed. The bag is effectively fully open on the top allowing maximum opportunity for materials to free fall and fill the bag.

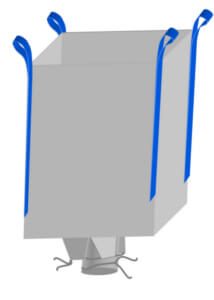

Plain base with no method for discharge.

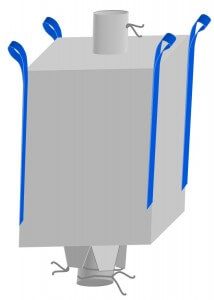

The most common way to empty a bulk bag is through a discharge spout. These spouts are folded (swan necked) and tied so they effectively form a flat base when not in use however when emptying the contents of the bag the spout can be untied and extended to allow the product to flow safely out of the bag. By adjusting the tie on the spout you can determine the radius of the discharge spout which will allow you to effectively control the flow rate of product being discharged.

Bulk bags can be designed with a full base discharge with four panels of material sewn into each side of the bag that cross over to form a flat base within the bag. The bag will also have an outer flap that can be securely tied. When untying the base outer flap, the four inner overlapped panels release to form a full base discharge.

Discover the top three reasons why businesses in the food industry need food-grade FIBC bulk bags:

Ensure the safety and integrity of your food products during storage and transportation with our food-grade bulk bags. Designed to prevent contamination and maintain freshness, these bags provide peace of mind for businesses like yours handling perishable goods.

Stay compliant with food safety regulations and standards by using our food-grade FIBC bulk bags. With their certified food-grade materials and hygienic design, these bags help businesses meet regulatory requirements and build trust with consumers.

Streamline packaging processes and improve efficiency with our food-grade bulk bags. Their durable construction and convenient features make them ideal for bulk packaging of food products, allowing businesses to optimise their operations and reduce packaging waste.

Most bulk bags and FIBCs are produced from type A fabric, a standard woven polypropylene fabric that won’t give you static protection. You shouldn’t use this bag where there’s an air dust mixture, explosive gas or flammable solvent atmosphere.

Type B bulk bags are also produced from non-conductive woven polypropylene fabric and have a breakdown voltage of maximum 6kV.Like type A bulk bags, you can’t use them as anti-static bulk bags as they can’t remove electro charge. As the fabrics used in type B bulk bags have a low breakdown voltage, they will prevent propagating brush discharges which can ignite an air dust mixture – but explosive gas atmospheres could still be ignited. You can use type B bags to safely store and transport dry flammable powders.

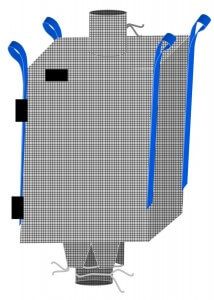

Also produced from a non-conductive woven polypropylene fabric, but with interwoven conductive threads that form a connected grid. The grid is a maximum of 50mm mesh size with a maximum distance between each other of 200mm (if the threads only go in one direction). These conductive threads are grounded whenever your bulk bag is filled and discharged. If they’re grounded correctly, there’s no risk of incendive discharges. You can use Type C bulk bags in environments where there’s an air dust mixture, as well as in explosive gas atmospheres.

Type D bulk bags and FIBCs are made from non-conductive woven polypropylene fabric with conductive fibres that aren’t connected to each other.

So this type of bulk bag isn’t conductive, but instead dissipates charge into the environment through corona discharge.

You have the option of treating these bags with an antistatic coating that reduces the surface resistance of the fabric. Because the electro-charge is dissipated through corona discharge, this type of bulk bag can charge conductive objects and people nearby, which could then cause electrostatic sparks on contact with grounded objects, possibly igniting air dust mixtures, explosive or flammable gas atmospheres nearby.

So it’s vital that whenever you’re filling or discharging a Type D bulk bag or FIBC in a hazardous area, all conductive objects or people nearby are grounded throughout. You’ll find full Instructions for grounding on the label of your Type D bulk bag.

Choose our bulk ordering options and get special rates for your food grade bulk bag needs. Talk to us today to get the best deal for your business.

Bulk bags can be manufactured to endless designs and specifications, depending on how you need your products to be filled, stored, transported and discharged. So it’s well worth thinking about:

Here’s our practical guide to the different bags we offer and how they’re constructed, plus some extra info to help you decide on the best one for you.

The name ‘bulk bag’ covers any kind of FIBC or flexible intermediate bulk container. They’re an ideal way for you to transport and store dry, free flowing materials safely, securely and cost effectively.

Yes! – Bulk bags can be made in a variety of different colours.

Yes you can! Bulk bags are made from Woven Polypropylene which is recyclable. Your bulk bags will need to be empty & baled for collection from a recognised Bulk Bag recycling centre to come and collect for you.

We carry a large range of stock items which are ready for immediate despatch. However, if you require something a little more bespoke these may need to be ordered in for you.

A bulk bag with a safety factory of 5:1 implies that the bag is only suitable for single trip use. A bag with a safety factor of 6:1 can be used multiple times, making the bag more environmentally friendly.

Our office opening hours are from 8am – 5pm Monday to Friday, excluding Bank Holidays.

Yes! – Bags can be printed to your requirements. Lead time on printed bags is 10-12 weeks with a minimum order of 500 – 1000 bags.

If your bags are in stock, you can come & collect the bags during our office opening hours, which are 8am – 5pm Monday to Friday (excluding Bank Holidays). However, if you require to pick your bags up out of these hours, please speak to our team who will be more than happy to accommodate for you.

Bulk bags have UV protection built into the WPP material used to create them. Woven polypropylene sacks and Net Sacks can have UV added by request.

Orders must be processed by 12pm for a next day delivery in mainland UK, additional charges will apply.

Yes! – We sell a variety of sizes in Vented Bulk Bags, Vented & Mosquito Bulk Bags and Log Net Sacks. Please visit our online store to view our vented bags.

All our orders are despatched on a 2-3-day eco-friendly service.

No – We only supply new, unused bags.

Bulk bags can be made for either single trip or multi-trip use, and you can find out which yours is from the safety label that’s attached to it.

A safety factor of 5:1 tells you that your bulk bag is for single trip use only – so you can only fill it once, but it can be lifted several times on its journey.

A safety factor of 6:1 tells you that your bulk bag is for multi-trip use and can be emptied and refilled several times – so this is your more economical and environmentally-friendly option.

The safety label will also tell you the ‘safe working load’ your bag can carry – for example, 1000kg. And it will tell you the test house, certificate number and certificate date, together with your bag’s manufacture date and batch number. All of this info is given to show that your bag’s been tested to perform to a safe standard, and so you can trace every step of its production.

Bulk bags can be certified to carry contents weighing anything from 50kg up to 2000kg. The heavier your product is, the heavier the grade of fabric needed to manufacture the bag so it conforms to the safe working load. A bulk bag can carry up to 1000 times its weight.

Food-grade bulk bags are predominantly made from virgin polypropylene resin which meets food-grade requirements for both storage and preparation.

The polypropylene is extruded in tubular form and then sliced into threads and woven together (warp and weft) to form a very strong, durable fabric.

Perfect for transporting and storing sand, our heavy-duty bags bring you minimal leakage and maximum convenience.

Keep your garden clean and organised with our durable bulk bags designed for garden waste disposal.

Designed to withstand the toughest conditions, our heavy-duty bulk bags give you reliable containment and transportation solutions for a wide range of materials and industries.

From construction sites to industrial facilities, our heavy-duty bulk bags offer the robustness you need to handle heavy loads and rough handling.

And with our longstanding team of experts, comprehensive knowledge of hundreds of products, thorough understanding of your sectors and commitment to sustainability, we’re perfectly placed to provide the solutions you need.

Ready to help with everything from small last-minute requests to large-scale, ongoing projects, our multiple sites, large storage facilities, international suppliers and flexible turnarounds mean we’re the team you can count on when it matters most.

It’s a level of reliability that’s built on 25 years’ industry-leading expertise and invaluable insight into your challenges and needs.

But we know that nothing stands still.

So as your industries – and needs – continually evolve, we evolve alongside them, making sure we always remain the supplier you can count on.

If you’re looking for bulk bags shipped fast and free, head to our sister company, The Bulk Bag Store.